Ok guys, so after the looooong wait, finally.....here is my retrofit write up.

2008 SuperDuke HID Bi-Xenon projector Retrofit project:I purchased the following from

They are great guys to deal with & have really good customer support.

Sportbike Stage III Kit, which comes with:

- Ballast: Morimoto 3Five (35W)

- Bulb: Morimoto 3Five 4300K

- Projector: Morimoto Mini Bi-Xenon (D2S)

- Shroud: GTi-R

- Wire Harness: H4

Also purchased a roll of butyl glue strip separately.

1. Start by taking off the complete headlight assembly. Before I unplugged all the connectors, I took lots of photos, just incase I had problems re-

connecting them. Taking the assembly off only requires removal of the two allen cap screws at the top & two pins (held on with clips) at the bottom.

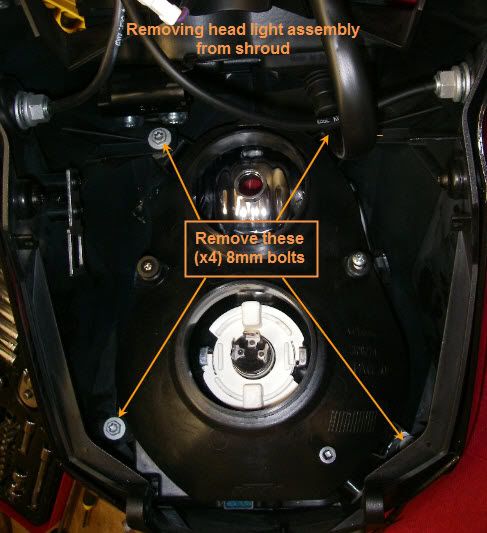

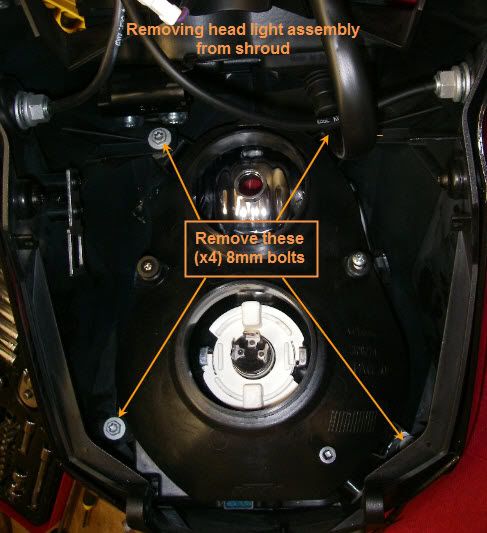

2. Once the headlight assembly is off the bike, then dismantle the actual headlight from the assembly. Remove the little smoke flip screen (4x allen cap

screws). In front, just below the instrument panel, is a self taping philips screw, take it out (this allows for the mask housing to split in two). Then

take out the four 8mm bolts holding the headlight to the housing. Once these are removed, you can separate the headlight from the housing. I put

some bubble wrap over my instrument clocks just to protect them from being scratched while being stored.

3. Now you’re ready to separate the headlight. I first, very carefully ran an X-Acto knife along the edge of the shield to slit the glue line. Our European bikes have the perma-seal glue holding the front lens to the rear housing (it sticks like crazy & is very hard) Most Japanese bikes have the softer butyl rubber glue, which comes apart real easy.

Turn on your oven & pre-heat it to 265 degrees F. Place the headlight in the centre of the oven for 7 minutes. Put on some mechanic/work gloves. After 7 minutes, take it out & very carefully start to pry the lens away from the housing. I had to put it back into the oven for another 7 minutes to further soften up the glue. You can use a flat blade screwdriver to help pry the lens away, but be Very Careful, it wont take much to damage the housing, scratch the lens or snap one of the locking tabs. Just be patient, take your time & it will come apart. You may even need another 7 minutes in the oven. Once you have it all separated, use some rubbing/isopropyl alcohol & a scalpel/X-Acto knife to clean off as much of the perma-seal glue as possible.

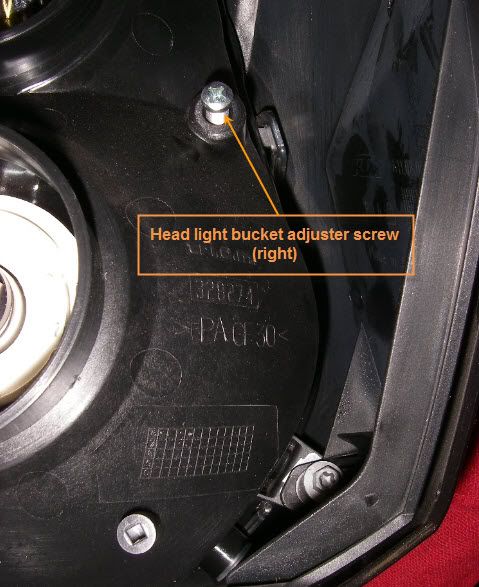

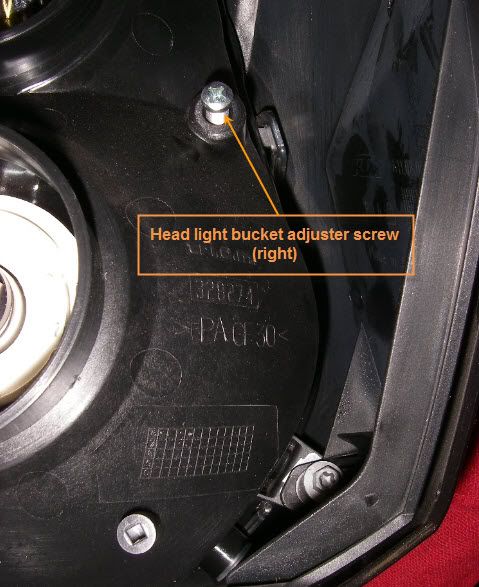

4. Now you can separate the reflector bucket from the rear housing. Back out the adjuster screws on the rear of the housing & the reflector bucket will pop off. NOTE: before backing the screws out, make a note of how far they are screwed in. A digital camera makes life a lot easier to snap pics as you’re going along.

5. Next I had to Dremel out the existing light bulb hole in the reflector bucket. I had to increase it to 34mm to accommodate the new projector.

I cut out a piece of steel keystock & JB welded it to the H4 adapter. This will provide a way to hold the H4 adapter in place when cinching down the lock nut and keep the projector on the correct horizontal plane (parallel) to the horizon.

I also replaced the stock white silicone crush washer with a black O-ring (1/8" diameter ring, 1 1/8" I.D., 1 3/8" O.D.) I did this to allow more gap between the projector lens & the headlight lens. You’ll need it for when you adjust the headlight range up or down.

6. I then sanded down the reflector bucket using 280 grit water sand paper. Sprayed it satin black using Krylon Fusion plastic spray paint. Seeing as the reflector is no longer going to be used for light production, & it just plain looks better black IMO.

7. I opted for the GTi-R shroud for the projector. This was the one, which gave the most coverage around the projector housing & was low profile enough not to come in contact with the headlight lens.

Assembled the projector into the reflector bucket. Re-attached the reflector bucket to the headlight housing. I opted to use some butyl glue strip for re-assembly…just a lot neater, easier & cleaner than using silicone or perma-seal.

Then, back into the pre-heated oven at 265 degrees F for 7 minutes. (Remember your gloves again) As soon I removed it from the oven, I made sure all clips etc… lined up & then clamped (using 12” ratchet bar clamps) the lens in place for 30 minutes until everything had cooled down.

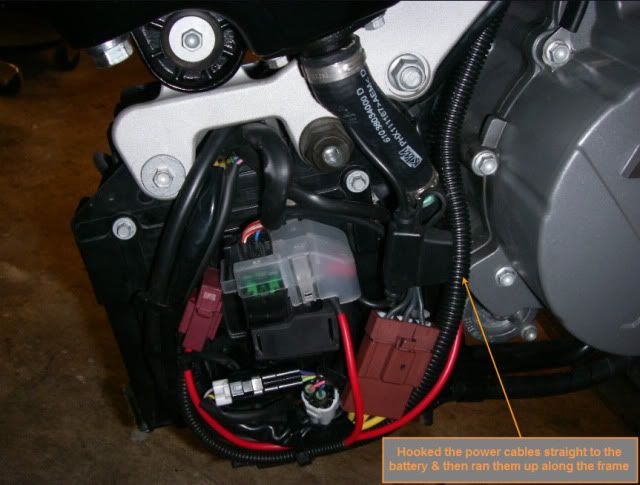

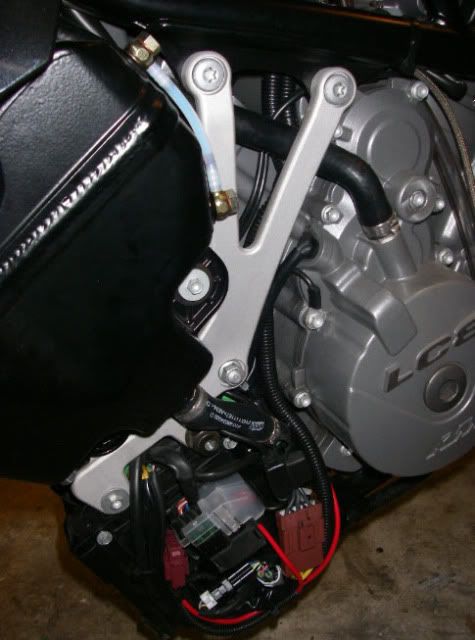

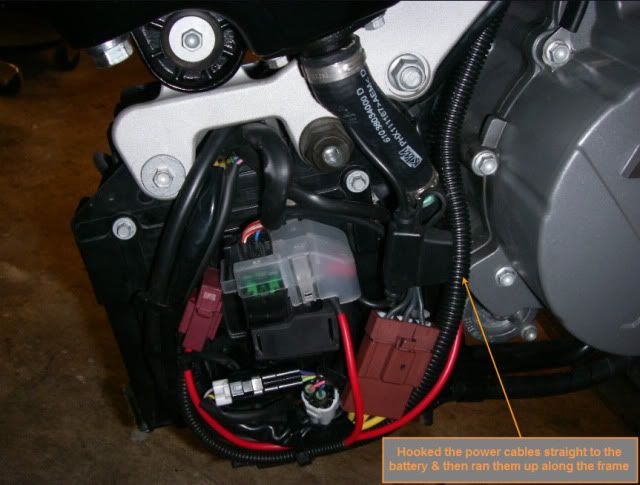

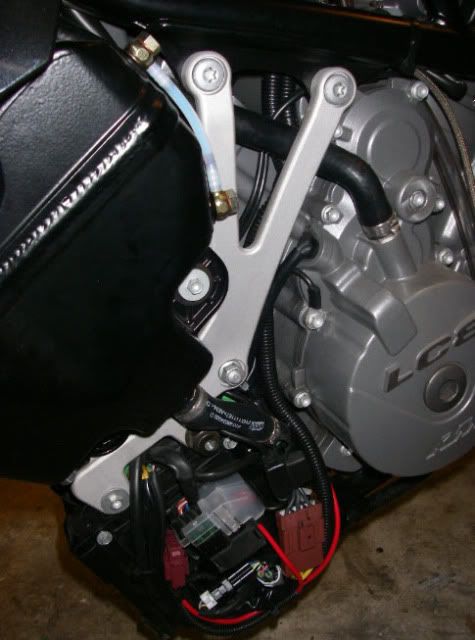

8. In between waiting for the paint to dry, I ran the wiring up from the battery & located the ballast behind the headlight (on the left hand side).

The Retrofit Source website has good explanations of how to wire it all up.

9. Re-installed the head light assembly into the shroud. Re-mounted it to the bike, re-connected all the wires & tucked the new wiring away behind the headlight. Buttoned everything up & set the headlight range. All done……well almost….lol…while I had the head light shroud off I decided to wire in some new smaller LED turn signals…they sure do look better than the big stock ones.